Skylights Without Skylight Railings or Screens Are More Dangerous Than They Appear

Installation of Non-Penetrating Skylight Guards and Screens Comply With OSHA Section 1910.23

Skylight railings, guards and screens (cages) absent around or over skylights, such as OSHA-compliant non-penetrating railing, pose a “blind danger”. Skylights are among the most dangerous areas on any roof. To the untrained eye, they might appear safe, as there is no visible opening; however, they are not designed to support the weight of a falling worker. Structurally, they are no different than a hole in the roof, and OSHA properly considers them as such.

Skylight railings, guards and screens (cages) absent around or over skylights, such as OSHA-compliant non-penetrating railing, pose a “blind danger”. Skylights are among the most dangerous areas on any roof. To the untrained eye, they might appear safe, as there is no visible opening; however, they are not designed to support the weight of a falling worker. Structurally, they are no different than a hole in the roof, and OSHA properly considers them as such.

Numerous deaths have been caused by workers accidentally backing into a skylight and falling through to the floor below. That is why OSHA 1910.23(a)(4) requires that “Every skylight floor opening and hole shall be guarded by a standard skylight screen or a fixed standard railing on all exposed sides.” Despite the fact that this has been an OSHA priority for over 30 years, thousands of buildings throughout the country are still not in compliance, even when workers are performing tasks in the immediate area of a roof. All too often the exposure is not realized until a worker is killed.

Skylight Guardrails or Screens Provide The Barrier Needed For OSHA Compliance

As noted in the OSHA regulation mentioned above, the two main methods for guarding this hazard are railings (guardrails) and screens (safety covers):

Guardrails

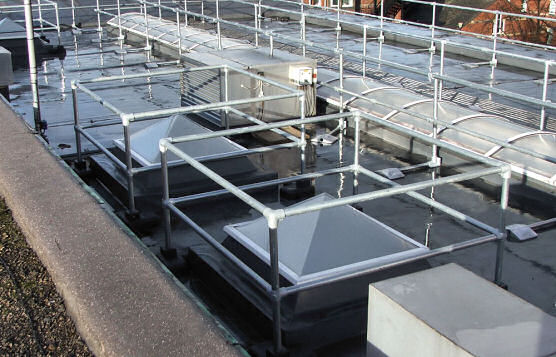

- Installing a skylight guardrail system works exactly as you would expect it to. It provides a fixed barrier, preventing a worker from accidentally entering a danger zone. Modular, non-penetrating systems can be assembled in different combinations around almost any configuration. Installation is simple, inexpensively providing both worker safety and OSHA compliance. Because it is non-penetrating, it can be dismantled and removed during roof replacement when alternate forms of fall protection are used, and replaced at the end of the project.

Screens

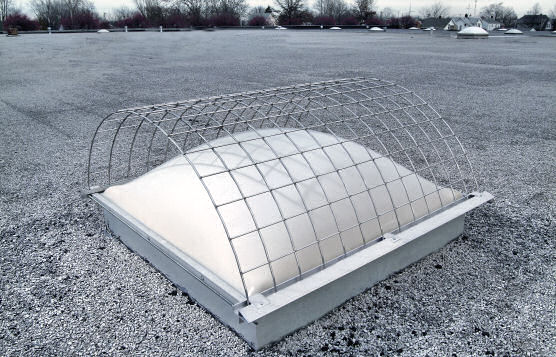

- Skylight screens are available in a wide variety of styles, allowing them to be used for any type of frame on any type of roof. They work by protecting the light itself, rather than by creating a barrier to the area. Because they are more visible than guardrail from the floor below, they are most often used with opaque windows. To meet OSHA requirements, the screen must be capable of withstanding a load of at least 200 pounds applied perpendicularly at any one point on the screen (CAL-OSHA requires 400 pounds). As with modular guardrail, the screens are non-penetrating. Using standard tools, the screen is attached to the sides of the base, and locked into position using clamping rings. They utilize a compression assembly that requires no drilling into either the roof or the base.

The following are examples of applications for these solutions:

We are authorized distributors and installers for the following manufacturers:

- BlueWater Manufacturing

- Capital Safety/DBI Sala

- Kee Safety

- Perimeter Protection Products

- The Bilco Company

- FabEnCo Safety Gates

- Guardian Fall Protection

- Lapeyre Stairs

Call us to arrange a free on-site assessment, and to discuss the various ways we can help protect your workers.