Anchorages – Certified Verse Non-Certified

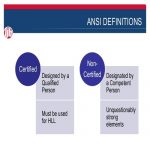

This blog will discuss the difference between Certified and Non-Certified Anchorage. The main differences between Certified and Non-Certified Anchorage are the different categories of anchorage, the design loads for these anchorages, and who is qualified to authorize the usage of the anchor. Anchorages fall under five unique categories: Fall Arrest; Work Positioning; Travel Restraint; Horizontal Lifeline-Rigid Track; and Rescue and ANSI Z359 provides distinct loading requirements for each. The following design loads- the maximum amount of something a system is designed to handle- specified in the ANSI Z359.2-2007.

This blog will discuss the difference between Certified and Non-Certified Anchorage. The main differences between Certified and Non-Certified Anchorage are the different categories of anchorage, the design loads for these anchorages, and who is qualified to authorize the usage of the anchor. Anchorages fall under five unique categories: Fall Arrest; Work Positioning; Travel Restraint; Horizontal Lifeline-Rigid Track; and Rescue and ANSI Z359 provides distinct loading requirements for each. The following design loads- the maximum amount of something a system is designed to handle- specified in the ANSI Z359.2-2007.

Fall Arrest: Non-Certified 5,000 LBs and Certified 2 x maximum arresting force

Fall Arrest: Non-Certified 5,000 LBs and Certified 2 x maximum arresting force- Work Positioning: Non-Certified 3,000 pounds and Certified 2 x foreseeable force

- Travel Restraint: Non-Certified 3,000 Pounds and Certified 2 x foreseeable force

- Horizontal Lifeline and Rigid Track: Certified only 2x maximum tension

- Rescue: Non-Certified 3,000 pounds and Certified 5x applied load

Certified Fall Protection Anchorage Points and Qualified Persons

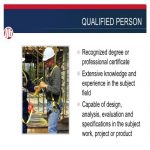

Certified Anchorages are identified by a qualified person- means one who, by possession of recognized degree certificate, or professional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated his ability to solve or resolve problems relating to the subject matter. After a qualified person identifies a Certified Anchorage a system is designed and these systems are usually permanent fixtures of the structure. When a permanent system is installed, the part of the building upon which it is being affixed needs to be able to support two things. The anchorage needs to be able to support the weight of the system and to support the potential forces exerted by a falling worker.

Certified Anchorages are identified by a qualified person- means one who, by possession of recognized degree certificate, or professional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated his ability to solve or resolve problems relating to the subject matter. After a qualified person identifies a Certified Anchorage a system is designed and these systems are usually permanent fixtures of the structure. When a permanent system is installed, the part of the building upon which it is being affixed needs to be able to support two things. The anchorage needs to be able to support the weight of the system and to support the potential forces exerted by a falling worker.

Competent Persons and Non-Certified Anchorage Points

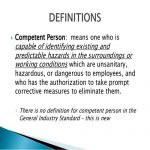

Non-Certified Anchorage- is an anchorage that is selected by a competent person- means one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them- after a visual inspection of the location. In order for a competent person to designate a point as a non-certified anchorage point. They must visually inspect the location and decide whether or not that area is capable of supporting 5,000 pounds or other supporting weight depending on the category of anchorage. Non-Certified Anchorages are typically used for a temporary solution.

Non-Certified Anchorage- is an anchorage that is selected by a competent person- means one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them- after a visual inspection of the location. In order for a competent person to designate a point as a non-certified anchorage point. They must visually inspect the location and decide whether or not that area is capable of supporting 5,000 pounds or other supporting weight depending on the category of anchorage. Non-Certified Anchorages are typically used for a temporary solution.

Certified Fall Arrest System Design and Documentation

A Certified Anchorage is one where there is documentation that the system meets the requirements of the standard and where a qualified person identifies the anchorage and designs the system. In contrast, a non-certified anchorage is one that a competent person can judge to be capable of supporting the predetermined anchorage forces and incorporates an energy-absorbing device. Certified Anchorages will be designed by a qualified person and installed with a permanent solution in mind and give employers flexibility in providing solutions. Non-Certified Anchorages give employers the ability to work in areas that a permanent fall arrest system is not a viable option. This is why when it comes to fall protection it is important to understand the work being done and how you are going to eliminate a fall risk. Certified and Non-Certified Anchorage provide a variety of solutions depending on the type of system you are looking to use.